KEY HIGHLIGHTS

- Today's engines have become more complex than before.

- An engine is the car's heart and oil its blood.

- Stricter emissions & need for efficiency - these demands are at their peak

- We tell you why good modern engine oils are essential for your machine

Introduction

Automotive synthetic oils - also known as lubricant oils - have also achieved high degrees of sophistication and excellence to meet the latest performance and vehicle emission standards. Besides protecting the engine's internal components from faster wear, these modern engine oils now also enhance fuel efficiency and reduce overall vehicle emissions.

Considering the complexity of modern engines featuring new-age technologies, the need for advanced lubrication has emerged stronger than ever. Here, we will discuss how long the technologies around engines and lubricants have come and how efficient they are in their functionality. However, before going further, join the 91wheels WhatsApp Community to keep up with the latest news and automotive updates!

Evolution of Modern Engines

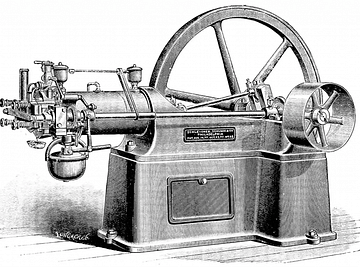

The origins of internal combustion engines go back to the late 19th century when Nikolaus Otto developed the first-ever four-stroke gasoline engine in 1875. It was followed by a high-speed petrol engine developed by Gottlieb Daimler and Willhelm Maybach for automobiles in the 1880s. These early engines had issues like improper cooling, poor efficiency and low reliability.

In the early 20th century, four-stroke petrol engines gained widespread popularity, which was initiated by the mass production of the Ford Model T that began in 1908. Forced induction technologies like turbocharging and supercharging were introduced in the mid-20th century, which improved acceleration, power output and efficiency at the same time.

The late 20th century saw the transitioning of internal combustion engines from using carburettors to modern fuel-injection systems using an electronic control unit and sensors for a more regulated air-fuel mixture. This switch to fuel injection systems helped the carmakers to achieve smoother acceleration, lesser vehicle emission levels and higher fuel efficiency.

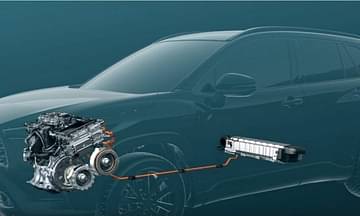

In the early 21st century, carmakers started introducing hybrid engines to achieve higher efficiency and cleaner mobility. Electric motors and batteries were also added to powertrains to reduce emissions and increase efficiency. In later years, carmakers adopted more advanced engine management systems and biofuels in sync with other environmental awareness measures.

Challenges for Traditional Lubricants

The wider acceptance of more efficient and cleaner synthetic engine oils has only exposed the shortcomings of traditional lubricant oil based on mineral oils. Following are the challenges faced by traditional lubricants in all these years, which have only increased more:

- Unlike synthetic oils, which can operate at a wider temperature range, traditional lubricants do not perform efficiently at extreme temperatures.

- Dirt particles and moisture, which are more prone to contaminants, reduce the effectiveness of traditional lubricants.

- Given their dependency on fossil fuels for base oils, traditional lubricants contribute more to greenhouse gas emissions and vehicle emission.

- These old-generation lubricants also pose a higher risk of environmental contamination due to the harmful by-products produced in their manufacturing and consumption.

Also see : how to change your car's engine oil at home - step by step explanation

How Modern Engine Oils Address These Challenges

As a tropical country, India faces a fair share of climatic challenges associated with extreme summers and equally extreme winters in its northern regions. High air pollution and dust add to these concerns, further affecting the functionality of engine oils.

Thankfully, we now have modern engine oils for passenger cars and SUVs to combat these adversities. Suitable for hot and dry climates, these engine oils keep the engine's internal components in check even in extreme temperatures. These synthetic oils also prevent the infiltration of dust and sand into the engine, further reducing the wear-and-tear rate.

Besides this, some synthetic engine oils also claim to enhance the overall performance and efficiency of the vehicles with their consistent lubrication due to optimal viscosity levels. These lubricant oils reduce friction between components, resulting in smoother engine operation and driving experience.

Key Features of Advanced Lubricants

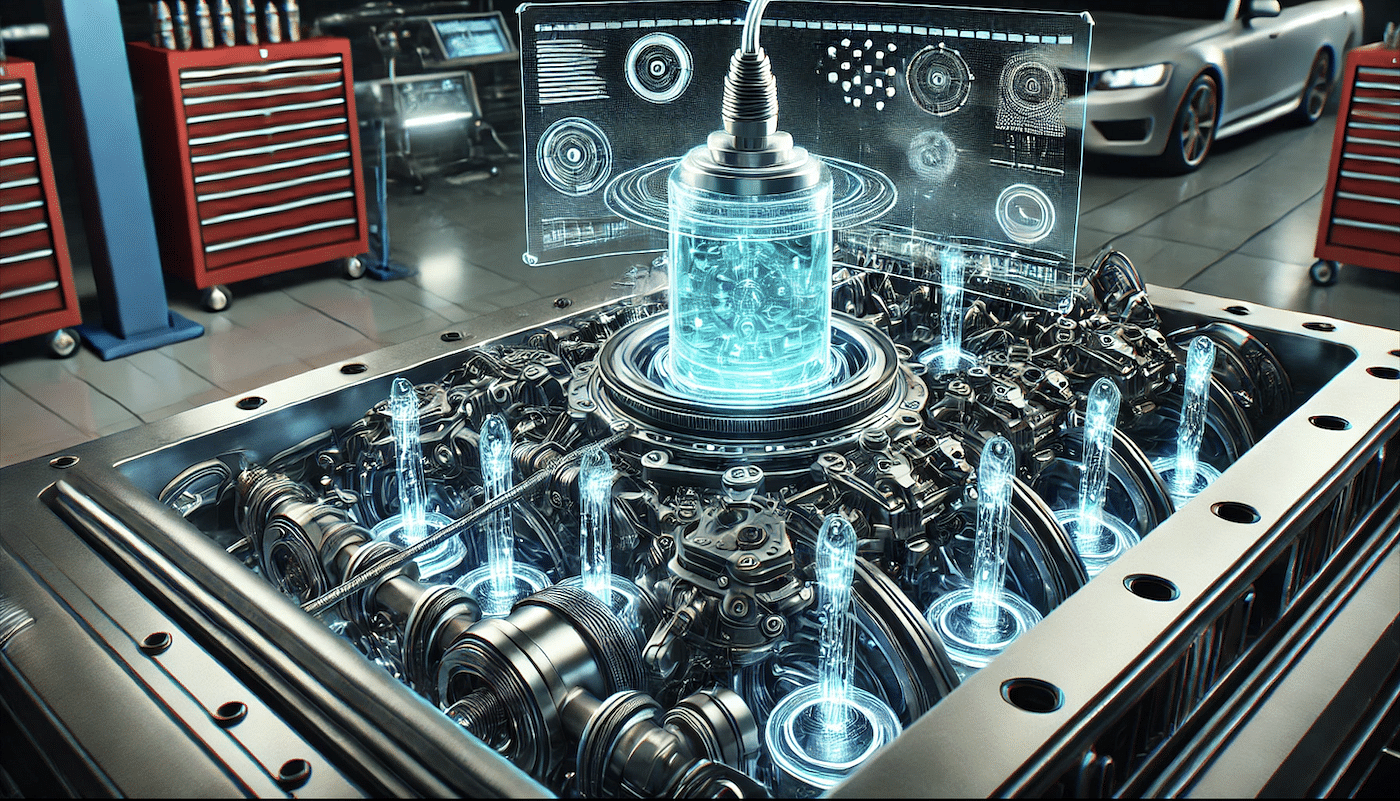

The advanced lubricant oils developed for vehicles nowadays come with various additives for surface protection, enhancing performance and lubricant protection. Some of the commonly-seen additives in the advanced lubricants are as follows:

Surface Protective Additives

- Anti-wear agent - It reacts with the metal surface and forms a thin layer with a lower shear strength than the metal surface, and prevents scoring and seizing by preventing metal-to-metal contact.

- Corrosion and rust inhibitor - It prevents the formation of rust over the metal surfaces by forming a protective layer over them.

- Detergent - It restricts the accumulation of deposits by chemically reacting with the sludge deposited on the metal surface and making them soluble.

- Dispersant - It separates the insoluble soot with the help of chemical bonding between its molecules and contaminants.

- Friction modifier - It alters the coefficient of friction by adsorption of surface-active materials.

Performance Additives

- Pour Point Depressant - This allows the smoother lubricant flow at lower temperatures.

- Seal Swell Agent - It swells elastomeric seals by chemically reacting with the elastomers.

- Viscosity Improver - It reduces the effect of temperature on oil viscosity.

Lubricant Protective Additives

- Anti-foaming agent - It prevents the formation of a persistent foam in the lubricant by reducing surface tension.

- Anti-oxidant - It retards the decomposition of oxidants by eliminating free-radical reactions.

- Metal deactivator - It lowers the catalytic effect of metals on the oxidation rate by forming an inactive film over the metal surface.

Benefits of Advanced Lubrication for Modern Engines

Besides offering the benefits of conventional engine oils, the new-generation advanced lubricant oils and synthetic engine oils offer more functionality and advantages, all of which are as follows:

- Lesser friction between engine components - Less friction between engine components results in smoother operation, which decreases energy losses and increases fuel efficiency.

- Reduced wear-and-tear rate - Lubricant flow over and around engine components like pistons, cylinders, and bearings smooths their operation, reducing their wear.

- Better heat dissipation - Lubricants allow faster heat absorption and dissipation between an engine's moving components, restricting overheating.

- Better performance at extreme temperatures - Synthetic oils can operate in a wider range of temperatures with the help of additives, making them more effective in extreme hot and cold climatic conditions.

- Protection from corrosion - The additives in the lubricants also prevent the formation of rust over metallic surfaces of the engine components, especially those exposed to dirt, dust and moisture.

- Lesser emissions - The reduced friction between the engine components also reduces the amount of pollutants and ash after the combustion of fuel, which eventually decreases the vehicle emission from the engine.

Conclusion

A lot has changed in all these decades of developments in internal combustion engine technologies, along with fuels and lubricant oils for them. The advancements in powertrain technology and cleaner fuels to meet performance requirements and stricter emission norms have led to equally significant developments in lubricant technology.

Verdict

With higher degrees of sustainability, efficiency and performance achievable by future powertrains in the years to come, it's only a matter of time before the developments in lubricants get more advancements.